Home › Forums › Modifications & Enhancements › Windscreen wiper mechanism

Tagged: Windscreen wiper mechanism

- This topic has 15 replies, 6 voices, and was last updated 3 years, 9 months ago by

Tresjolie.

Tresjolie.

-

AuthorPosts

-

-

17th April 2019 at 19:55 #1038

Hello folks, I know many people have had the dreaded wiper failure whereby the motor mount has dropped off causing the wipers to fail. Anyone who has suffered this design fault will have found their own way to overcome it but I thought I would share my ‘fix’ which is still going strong after several years. Basically I purchased some cheap roofing rafter straps from a DIY store and used like giant Mechano (showing my age now!) to fashion a new sturdy support for the wiper motor. I found a number of small pre-drilled threaded hole in the engine bay that weren’t being used, so I used these to attach my new frame to the body. As the metal straps were pre-drilled along their entire length it was very easy to cut and bend them into the required pieces so that the holes aligned easily when it came to bolting them together. The whole job took about an hour or so, but it was a bit fiddly as it was a ‘make it up as you go along’ type of job. Best wishes, Ted.

-

17th April 2019 at 21:49 #1040

Now that IS clever, Ted. It saves a lot of heartache trying to fabricate tubes/rods/straps to beef up the motor mechanism.

It’s recommended that ALL owners reinforce their “wobbly” wiper motors before they self-destruct, as some unlucky owners have experienced.

Best wishes,

Barry

-

6th February 2020 at 18:45 #2404

I recently became aware that my wipers had become slow and a bit laboured. Having read the threads about self destructing wipers, Decided to investigate under the bonnet.

When the wipers were switched on, there was some flexing and movement of the motor.

A spray of Lidl GP oil followed by a generous squirt of lithium grease on all of the linkages and pivots cured the problem. Hopefully I have nipped it in the bud and won’t have to do any reconstructive surgery.

Because the mechanism is not obviously visible, it probably doesn’t get the attention it needs……until it goes wrong. Mine obviously didn’t!

It’s now on the list with hinges, locks, rubber seals and the roof window mechanism.

Nozzi

-

This reply was modified 4 years, 2 months ago by

nozzi.

nozzi.

-

This reply was modified 4 years, 2 months ago by

-

6th February 2020 at 19:49 #2410

In this case, a stitch in time, eh? A good warning to us all… a bit of lubrication on these joints could prevent a lot of strain on weaker components.

Don’t use WD40 folks – a common error, it’s not a lubricant. Better to use a proper lubricating spray, like the one Nozzi’s found, or 3-in-One, or even some drops of engine oil.

Thanks, Nozzi.

Barry

-

6th February 2020 at 19:49 #2411

In this case, a stitch in time, eh? A good warning to us all… a bit of lubrication on these joints could prevent a lot of strain on weaker components.

Don’t use WD40 folks – a common error, it’s not a lubricant. Better to use a proper lubricating spray, like the one Nozzi’s found, or 3-in-One, or even some drops of engine oil.

Thanks, Nozzi.

Barry

-

7th February 2020 at 18:26 #2412

I spray white grease around all moving parts.

Another good point to remember is something that Tom pointed out long ago…..make sure that the insulation for the cab extension does not inhibit free movement and trim back if necessary.

It was me who initiated the beefing up of the support brackets after mine failed a second time in 2016 when the drive arm fractured in exactly the same place as before, where it is flattened. In previous observation I had noticed a fair bit of movement of the existing Hymer set up and that flimsy support stay back to the bulk head. I modified mine quite simply using the spare original Fiat motor bracket that came with the replacement wiper unit from the breaker yard. I demonstrated this at the 2016 Exsistravaganza and made others aware of the movement and flexing by us all looking at other vehicles.

It came as a surprise to all and keen interest followed along with some subsequent beefed up modifications from Harvey and Tom, ….. others followed such as Hector.

<p style=”text-align: left;”>Think mine looks a little neater than all that angle everywhere and fingers crossed has stood the test of time. |As we can only post one image I am showing what mine looks like and will do a separate image to show what I did.</p>

Fred -

7th February 2020 at 18:43 #2413

I never posted my mods as I was keen to see what others would do – I did write copious notes which I have now lost and in any case lots of photos and ‘how to’ is a little difficult to post one at a time.

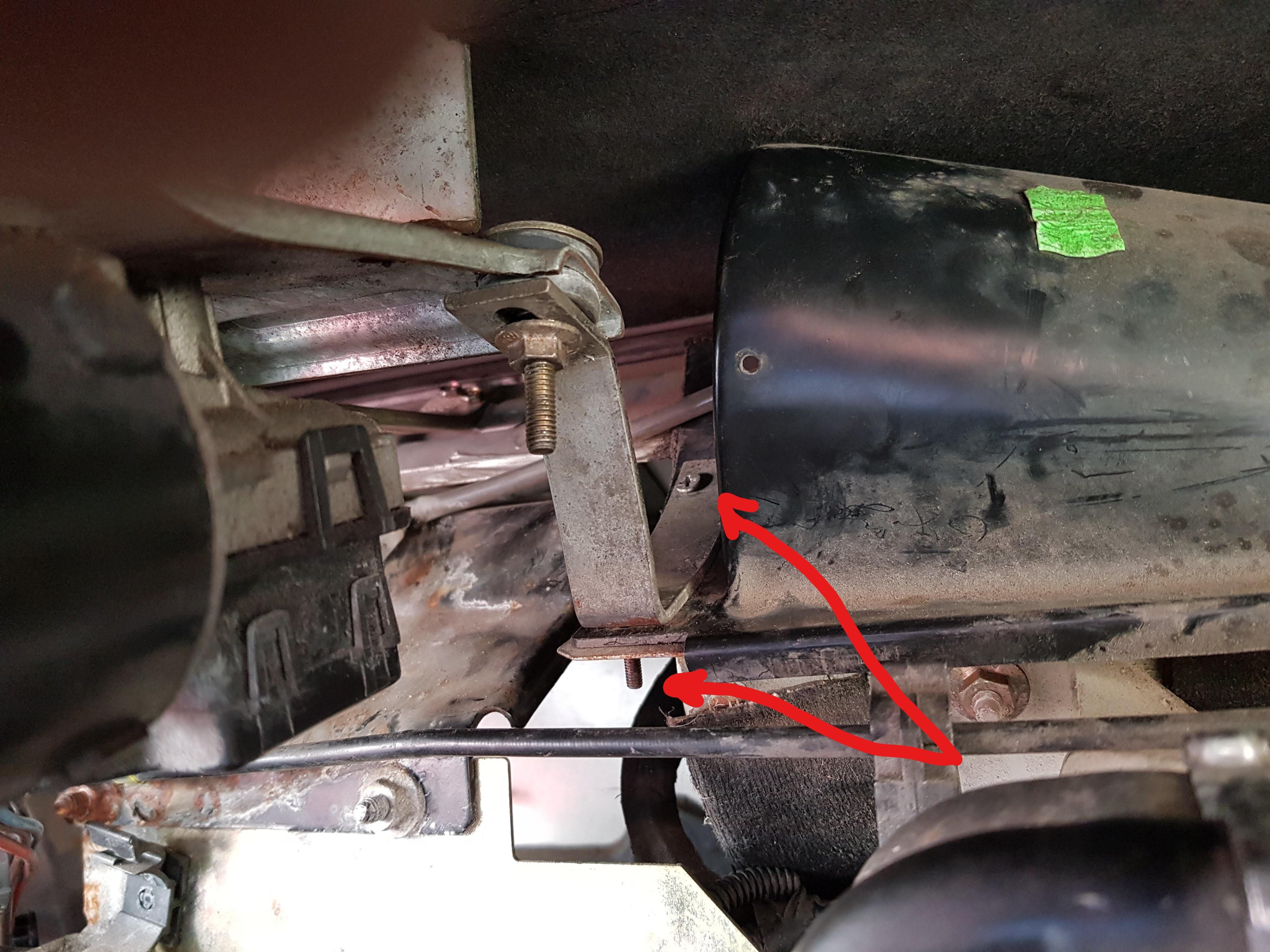

I worked out that the Fiat wiper motor support bracket inverted was not to dissimilar to fit onto the black metal plate from the bulk head below the unit….so I cut some off the wide end and made some little cuts to bend the end at right angles and then with some angle iron bolted the modified piece to the original bracket. The bottom of the inverted support bracket was then bolted to the plate below – see the elements in their ‘offering up stage’ in the photo below.

Note the original Hymer stay back to the bulk head ( which is woefully inadequate) and Tom and I have replaced the original ‘Phillips’ self tappers with hexagonal head self tapper bolts.

Fred

-

7th February 2020 at 18:49 #2414

Here is another view.

Any more detail and I will have to get my thinking hat on – if I can find it!

Fred

-

7th February 2020 at 19:28 #2416

Thanks for all that info and those pics, Fred. Invaluable.

Er… ye-e-es… thinking hat… I think mine must’ve got thrown out! 😒

Barry

-

29th April 2020 at 11:28 #2649

Hi all,

Well as I’m running out of things to do I thought I could now spend some time letting you good folk know about some of my improvements done during this lockdown.

This one is the issue of the wiper mechanism. So after looking at all the various solutions owners have come up with I decided to do a little different and simples.

I wanted to secure this on the X and Y axis as best I could.

Here with parts removed are the points I would be securing the new brackets, the original bracket with 2 holes on rear bulkhead I would ‘beef’ up as its so flimsy.

-

29th April 2020 at 11:31 #2650

This will be the bracket to stop movement vertically.

-

29th April 2020 at 11:33 #2651

So I mounted the bracket to a solid anchor point on the lip of the air box. Secured with a nut and bolt fixing at the front but with restricted access could only secure back with a self tapper screw.

-

29th April 2020 at 11:39 #2652

Then to stop horizontal movement I replaced the original bracket with a much stronger one. I also upgraded the self tappers with larger self tapping bolts, secured to the rear bulkhead as original.

-

29th April 2020 at 11:42 #2653

The end result is …. hardly any movement at all with the wipers going – solid!

Happy with that.

More mods to come.

Regards,

Dougie

-

29th April 2020 at 15:39 #2660

Excellent idea and write-up, thanks, Dougie.

Keep ’em coming!

Barry

-

8th July 2020 at 14:46 #2889

I’ve replaced the replacement wiper mechanism because one of the spigots seized. Glad to see that the bar I put across the grill has done its job as the rear screw fixings have not budge. £54 for scrap mechanism

Tom

-

-

AuthorPosts

- You must be logged in to reply to this topic.